Shanghai-Plastic Machinery Manufacturing Co., Ltd. is located in

Shanghai's Songjiang Science and Technology Park, with a total area

of 238 acres. Its transportation is very convenient, located in the

Shanghai-Hangzhou Expressway and the same three motorway at the

exit port, and is adjacent to the city of Shanghai University and

Shanghai Metro Line 9 Terminal --- Songjiang Xincheng Station.

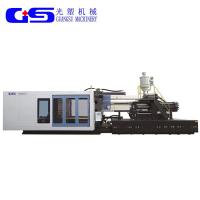

The company has consistently abide by the "quality products, star

service" business philosophy, "Light plastic" card injection

molding machine for its high quality, efficient, energy-saving

advantages known in the press industry. Its main products include

GM series of quantitative pump injection molding machine, HS series

servo motors GSV series of energy-saving injection molding machines

and variable energy-precision injection molding machines ranging

from 50 tons to 2,000 tons, injection volume from 30 grams to

10,000 grams of 40 kinds of specifications injection molding

machines and related auxiliary machinery, molds, and has

high-quality partner suppliers and extensive experience in the

plastic molding products peripherals. Annual output of more than

3,200 injection molding machines, sales network throughout the

country; while the products have been exported to Europe, Central

America, Middle East, Southeast Asia and Africa, such as Russia,

the United States, Romania, Turkey, India, Syria, Iran, Myanmar,

Nigeria, Cameroon more than 50 countries and regions, as well as

meet the needs of various industries products processing, the

company has developed a perennial plastics processing auxiliary

equipment suppliers and mold manufacturers to meet the needs of a

variety of products processing. The introduction of foreign

companies a full range of advanced CNC machining centers to ensure

excellent quality light presses, and in the first peer through the

ISO9001-2000 quality management system certification standards and

CE certification.

The company will follow the "technology-oriented, management

innovation, quality first, customer first" approach, continue to

increase new product development efforts, focusing on the

development of the leading domestic level and catch up with the

world's advanced level of a series of new products, let it be my

the company's new bright spot of economic growth. Also introduced

in the management and quality control a series of new initiatives

to strengthen cooperation with well-known domestic and foreign

research institutes and enterprises, well-built "light plastic"

brand, improve user satisfaction. Our entire staff under the

leadership of the board of directors of the company, determined to

carry forward the "unity, truth-seeking, dedication, innovation,

pioneering" spirit, to build the company for the domestic

first-class well-known enterprises. We sincerely thank all the

friends of the support and love, and warmly welcome customers to

visit us!

Plastic Machinery, create a bright future. We welcome foreign

businessmen to visit the guide, we will spare no effort to provide

customers with more comprehensive, more professional, more detailed

services to win new customers trust and support.